Commercial CNG Kit

CNG-run passenger vehicles are already popular among cost-conscious consumers, but diesel

is the preferred choice for commercial vehicles because the fuel offers better pulling power.

But the rising price of diesel is making buyers consider CNG options, as the cost savings are

significant. And also it is eco-friendly.

The basic maintenance rules apply for any CNG kits. Those maintenance tips are listed below:

1. Clean the Air Filter of the CNG kit at about 5,000 kms.

2. Replace the Air Filter of the CNG kit after 10,000 kms.

3. Replace the Spark Plug of the vehicle when it reaches 20,000 kms and no later.

4. CNG Kits come with CNG Cartridges which need to be changed at 20,000 kms for the Reducer Cartridge and 40,000

kms for the Low Pressure Cartridge.

5. Proper maintenance of the Spark Plug and Air Filter ensure an optimized performance.

Commercial vehicles are surprisingly multi-reason vehicles Emissions are cleaner, with lower emissions of carbon and lower particulate emissions per equivalent distance traveled. There is generally less wasted fuel. However, cost (monetary, environmental, pre-existing infrastructure) of distribution.

Components of 3W-CNG Kit

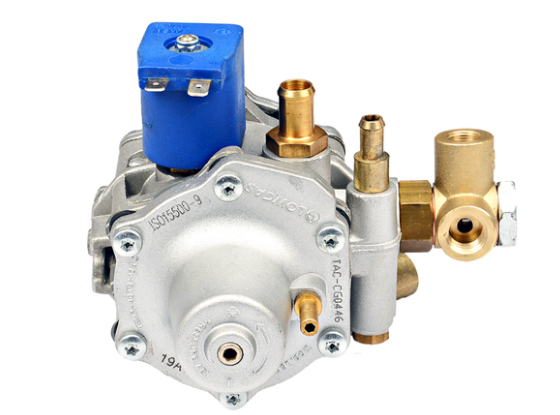

Reducer

A reducer has been designed to supply fuel-injected vehicles with CNG, and also offers excellent performance for MPFI vehicles. This reducer comes with a water-gas heat exchanger, filter, gas solenoid valve, and safety valve. The reducer is calibrated for a supply pressure of 2 bar (200kPa) and a nominal flow rate of 30 Kg/hour. These pressure reducers come in two stages diaphragm and piston based which are exclusively designed for being used with 5th generation systems. Clients appreciate these reducers for their excellent performance and safety features. The reducers are powerful Reducers. reliable under all working conditions and provides superior performance in comfort and drivability.

Cylinder

Compressed natural gas (CNG) cylinders aren't like your run-of-the-mill fuel tank. They are pressurized, which means users must take special precautions when it comes to proper maintenance, replacement, and disposal. A gas cylinder or tank is a Pressure Vessel used to store gases at above atmospheric pressure.

Injector Rail

The injector rail in a CNG sequential system is meant to inject the controlled quantity of CNG fuel at specific intervals of time (as programmed in ECU). The programming is done in such a way that the petrol injectors and the CNG injectors perform identically.

It is applied to liquefied petroleum gas and compressed natural gas Body made of shaped, blue/black anodized aluminum alloy for better heat exchange Plunger made of the special soft iron and it was treated by the special process of which greatly improved the stability of the injection valve dynamic flow The type includes 3- cylinders, 4-cylinders, 6-cylinders and 8-cylinders Our injector rail applying to a variety of engines.

Filling Valve

A filler valve equipped with a non-return check valve enables the CNG filling through the

CNG dispenser. Filling Valve is the valve through which the CNG is refilled in the gas cylinder.

We use filling valves that match with international standards and match the world’s class best quality.

Change Over Switch

The car starts (ignition), the orange light is ON indicating the car is on petrol, As we press accelerator (rpm increases), it automatically switches to CNG as it reaches the set rpm(programmed i.e. 1200 rpm) Greenlights become visible as the car is now running on CNG. The number of lights indicates the quantity of CNG available in the gas cylinder. Even if CNG is still available in a gas cylinder and you want to switch into petrol, then just press the switch once. It will be switched to petrol. You will not feel any knocking during fuel conversions.

Address

Address: DSR Complex 129 Y1, 1st Floor Lalbagh Main Road, Opposite Passport Office,Bangalore Karnataka 560027

Phone and Email

+ 91 9900423399

info@dsrecotech.com